Share This Article

In this article

What is ecommerce inventory management?

Ecommerce inventory management is a broad term used to describe the strategy and logistics necessary for sourcing, managing and fulfilling product orders within an acceptable time frame.

Processes involved in inventory management include:

- Forecasting future demand for inventory

- Sourcing inventory from wholesalers

- Managing wholesaler deliveries to your warehouse

- Managing inventory stored in your warehouse

- Shipping the product to your customers in a timely manner

- Tracking Purchase orders

From the moment that you purchase products from a wholesaler, to the moment it reaches your customer’s doorstep - inventory management is what makes the magic happen.

Creating and maintaining a strategy around your inventory management practices takes time and effort along with a whole lot of planning. The first step to improve your inventory management practices is understanding exactly what that entails.

Common inventory management terms to know

Minimum Viable Stock - the minimum amount of products and variants needed to keep up with demand and fulfilling orders without delay.

SKU - short for “Stock Keeping Unit”. These are the distinct types of items you have for sale. For example, if you sell 3 different plant pots then your company has 3 SKUs. However, if each pot can come in 2 different materials, then you have 6 distinct products which means you have to buy inventory for 6 SKUs.

JIT (Just-In-Time) Fulfillment Method - A method of a fulfillment where inventory is created, manufactured or assembled just in time to keep up with demand from consumers.

FIFO (First In First Out) Accounting Method - Shopify defines FIFO as “an accounting method assumes that sellable assets, such as inventory, raw materials, or components acquired first were sold first. That is, the oldest merchandise is sold first, with its associated costs being used to determine profitability.”

Inventory Auditing - The process of manually checking whether your physical stock matches up to the stock noted by the inventory management software which controls the tracking and management of your stock.

Carrying Cost - The yearly cost of holding unsold inventory.

Dead Stock - Inventory that did not sell during the forecasted period of time.

Stockout - When a company runs out of stock of a specific product which consumers are looking to purchase.

Centralized Inventory Control Software - A piece of software which allows merchants to track their inventory numbers when selling through multiple channels like Amazon, Shopify, eBay, etc.

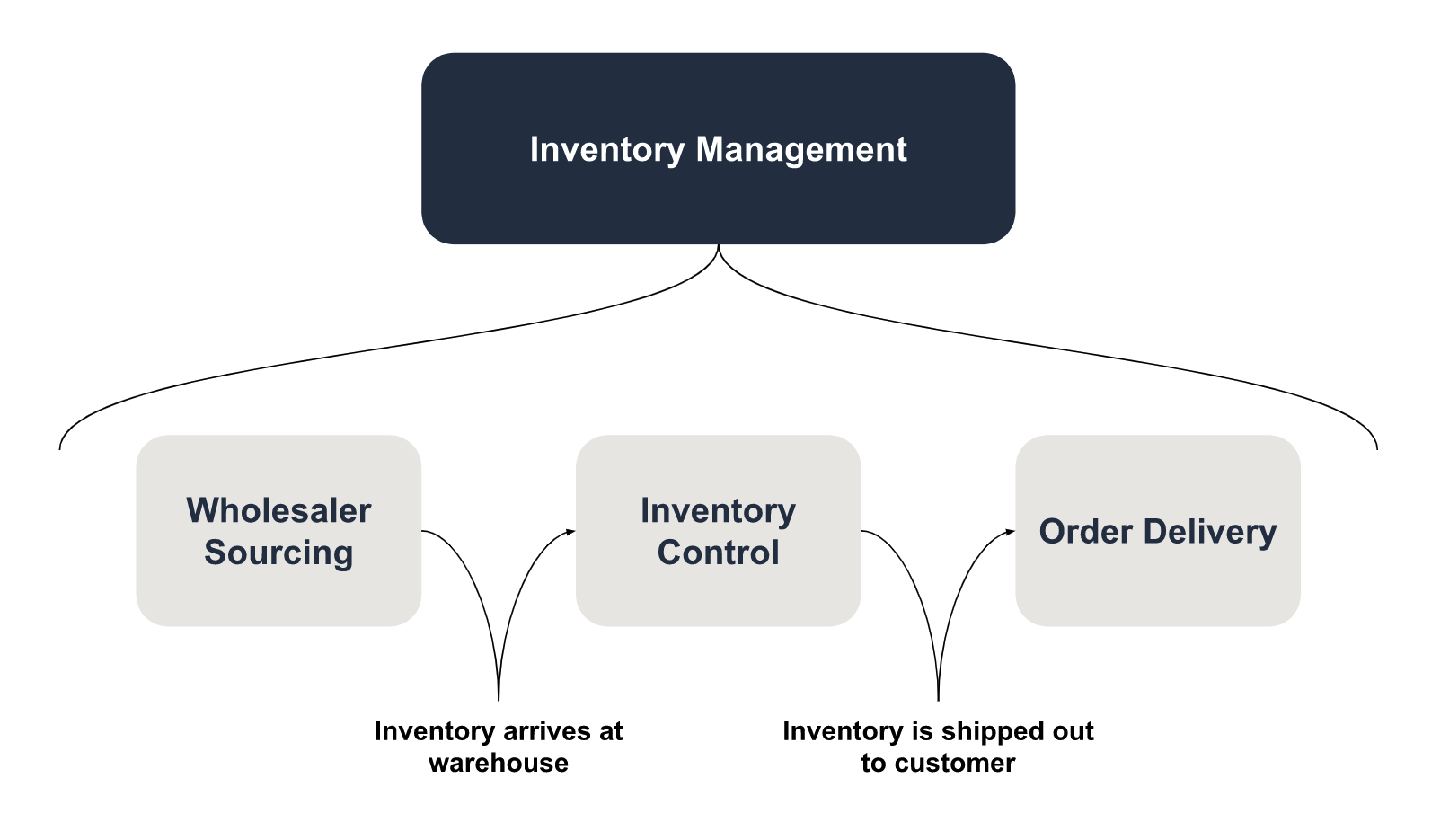

Inventory Control - The strategy around warehousing and fulfilling products after they’ve already been sourced.

What is the difference between Inventory Control and Inventory Management?

At first, it may seem that inventory control and inventory management are interchangeable terms. However, they are not.

Inventory control refers to the logistics between when a customer’s purchase order enters your warehouse system to it being shipped out for the customer. It is the systems and strategies in place to ensure that there are no stockouts or any other major issues with the inventory currently in your warehouses.

On the other hand, inventory management is a higher-level term which encompasses everything from sourcing the product from wholesalers to overseeing the delivery to the customer.

.svg)

Inventory control is a massively important piece of the puzzle to make sure you’re implementing effective inventory management practices. Improper inventory control can lead to major cash losses. For example, in 2014 Walmart estimated it missed out on $3 billion worth of sales due to inadequate inventory control procedures which led to stockouts.

The benefits of inventory management

There are two major concepts a retail company must understand in order to scale up and operate their business.

Firstly, they must be able to sell their products. This is a combined effort between sales and marketing functions. Whether you write a successful blog, run social media ads, or employ a sales staff - the primary goal is to sell your product.

Secondly, you must have proper inventory management practices. If you have a massively successful brand, but nothing available to sell because your warehouse is empty - there are going to be problems.

Inventory management is the largely overlooked pillar of eCommerce companies especially to business owners who are just starting out. The operations of an eCommerce look very different when you go from selling 100 units/month to selling 10,000 units/month. Likewise, the impact of bad inventory management worsens as the company grows in size.

There are many reasons why a business owner should implement efficient inventory management practices. The primary goal of improving your inventory management is to make sure your customer satisfaction stays high which will earn you brand trust and more dollars in the long run.

The primary reasons for good inventory management can be summarized as reducing warehousing costs, increasing revenue, increasing margins, and perhaps most importantly - building a reliable brand.

1. Reduce warehousing costs

Good inventory management means you have forecasted your customer demand correctly and therefore you know exactly how many units you expect to sell next quarter. If done properly, this means the business will avoid having any dead stock laying around and warehousing costs will be at their minimum since you warehoused the exact right amount of inventory.

2. Increasing revenue

Many companies suffer from stockouts, which are when products are listed as “out of stock”. For the business, this means that customers can no longer purchase that product even if they wanted to which means lost revenue. In order to avoid having any products be “out of stock” and maximize your revenue, proper inventory management practices need to be in place.

3. Increase your margins

Forecasting the right amount of inventory to buy means that not only will you avoid any stockouts or dead stock, but it also means you are able to properly negotiate bulk deals with your wholesaler which can increase your margins.

4. Building a reliable brand

The biggest reason to employ proper inventory management is that it will improve your customer experience in many different ways. When a customer receives their package on time and undamaged, that is the closure of your transaction with the customer. However, it is not the closure of your relationship with them.

Customers will see an ad for your store, or they will stumble across a blog post, or perhaps they will hear about it from a friend, and once they purchase something the clock begins ticking. If a customer received a damaged package or a delayed shipping notice, it will certainly threaten the trust in your brand. Nothing brings in more long term repeat clients than brand trust, and inventory management is one of the things necessary to achieve that.

The basics of inventory management

The Pareto Principle

The Pareto Principle, sometimes called “the 80/20 rule”, is considered a rule of thumb when planning and strategizing around your inventory needs.

Around the late 1800’s, an Italian economist named Vilfredo Pareto looked at his garden and noticed that 80% of his peas were coming from only 20% of his pea plants. After this realization, Pareto began seeing this pattern in many other places. Pareto concluded that 80% of all results, whether that be in business, economics, or gardening, derive from only 20% of the effort.

Because of this, it is often said that 80% of your sales come from the most loyal 20% of your customers. While the numbers may not be exactly the same as Pareto’s pea garden, the concept is very relevant to eCommerce businesses. Business owners need to understand who their most loyal customers are and study their purchasing behavior in order to ensure that those specific customers are getting exceptional service.

Pareto’s 80/20 rule can help us analyze our inventory management practices by helping you manage the products that matter the most. When Pareto’s principle is applied to inventory management, it is often simply called the ABC Analysis.

ABC Analysis

In an ABC analysis, all of your products are split into class A, B, or C based on how well they sell to your customer base.

Class A are the products that have the highest consumption value and are purchased very frequently. Class A products are therefore extremely important to always be in stock.

Class B are the products that are often purchased and are of medium value to your customer base.

Class C are the products that are not purchased often and have low consumption value to your customer base. Therefore would have the least impact in your business if they were out of stock.

(Graph by TC Creatives)

The products included in class A are always the most important for your inventory management practices. Running out of inventory of a class A product could severely damage your bottom line but also your brand image. For example, everybody remembers what happened when Popeye’s ran out of their Chicken Sandwich in 2019 at the peak of their battle against Chik-fil-A for best fast-food chicken sandwich. Popeyes reportedly lost millions due to the stockout of this class A product and Chick-fil-A was able to snatch a large portion of the market share because of this. Popeye's stockout stands as a warning to any companies who are not actively studying the purchasing behaviour of their customer base as it may severely stunt their brand’s growth.

The ABC analysis is a fantastic tool to understand how to prioritize your products when determining where to allocate your buying budget and marketing dollars. When thinking about inventory management, any team should always take some time to analyze the circumstances from the point of view of Pareto’s 80/20 rule.

All that being said, understanding which products are in which class requires intensive market research and data from the purchasing behavior of your consumers. This is why inventory tracking is an important piece of the puzzle when it comes to pulling in data-drive insights to inform your forecasting.

Forecasting and inventory tracking

Forecasting how much inventory you will need takes a keen eye, a lot of data and a sprinkle of luck that a random event won’t steer your inventory off a cliff - queue the massive shortages of toilet paper during COVID-19. Inventory forecasting can sometimes seem like magic when it goes right, and a terrible catastrophe when it goes wrong. Unfortunately for all of us, there’s no one right method of forecasting your inventory. However, the context of your company should be taken into account when beginning your forecasting efforts:

1. How old is your business? Older businesses have an easier time forecasting their inventory because they have a lot of first-hand experience for what the consumer behavior is like during each month of the year. This first-hand data especially if it was properly tracked using inventory tracking software can be extremely important to ensuring your business is protected from inventory shortages or dead stock.

2. Is your business seasonal? It should not come as a surprise that eCommerce stores selling snowboards make most of their money during the winter and flip flop companies make most of their money during the summer. Understanding when or whether your consumer demand is going to spike is vital to putting together an effective forecast.

3. Are you an international business? Different countries have different holidays which may mean different purchasing patterns and different shipping times and delivery logistics. Although business owners have a tendency to think of all their customers as largely homogenous, they are in fact different from each other and this is especially true when speaking of their geographical location and their logistics requirements.

4. Do you have a return & refund policy? If so, you will need to factor this into your forecasting to ensure you don’t end up with returned items that become dead stock.

In addition to asking these questions, business owners must keep in mind the 3 most important mechanics of a forecasting analysis:

Forecast Period

The forecast period is the length of time used to determine the exact inventory quantities you’ll need to order. The majority of time, eCommerce companies will either forecast their inventory needs on a month-to-month basis or on a quarter-to-quarter basis.

Choosing the correct time period for your forecast analysis will depend on how fast you sell through your products. If you sell through your products quickly, then you will need to repurchase new inventory more often and therefore your forecasting period will be short.

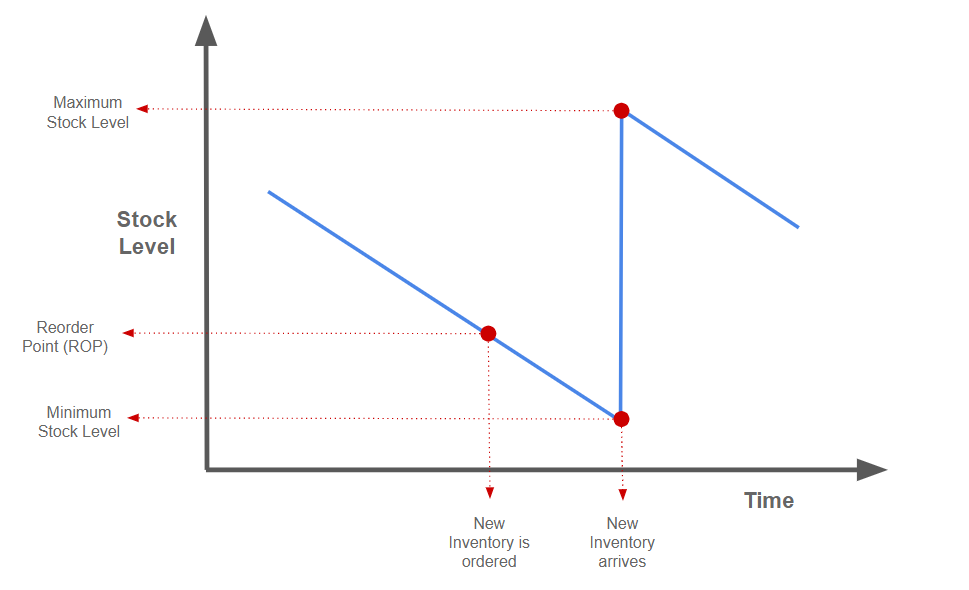

Maximum Stock Level

Your inventory will constantly fluctuate between its lowest point and the highest point due to consumers purchasing your product and new inventory arriving at the warehouse. The highest level your inventory will reach is known as the maximum stock level. This is the level you will typically aim for when reordering inventory with a slight increase to account for your expected growth during the forecasting period.

Reorder Point (ROP)

A reorder point (ROP) is the minimum quantity of inventory (per SKU) that a business should have in available inventory before they need to reorder more. It should be noted that the reorder point is higher in stock levels than the minimum stock level due to the delay between purchasing inventory, and having it arrive in the warehouse ready to be sold. Thankfully for us, ShipBob has created a handy formula for finding your reorder point.

Common ecommerce inventory management challenges

Financing your purchase order for new inventory

Finding the cash to buy new inventory can often be a deciding factor on whether you will be facing stockouts later in the month or in the year. If a business does not have enough cashflow to afford the correct amount of inventory they need to purchase, stockouts will become inevitable and the bottom line will show it.

Running out of stock due to poor inventory logistics is one thing. Running out of stock due to the lack of financing to buy new ones can be a death sentence.

There are many options available to help you finance new inventory. Perhaps the best one for an ecommerce business is the ecommerce line of credit from Loop which you can check your eligibility for here.

Overstocking & Understocking

One of the toughest challenges about inventory management is knowing how much stock to order so that you avoid having stockouts or being left with dead stock at the end of the month.

If you overestimated the consumer demand for a product you can end up with dead stock. This is called overstocking and it can be harmful to your bottom line as you will have to incur the carrying cost of having to hold onto unused inventory. For products with short shelf lives, this can be detrimental to the point that you lose the leftover stock altogether. For products with a long shelf life however, this problem is not as costly.

On the other hand, if you underestimate the consumer demand for a product, your product will run out of stock and your company will have to deal with the damage from a stockout.

Between the two, understocking can be the most harmful to your brand and your bottom line. When you are faced with a stockout, customers who want to buy your product are not able to and typically they turn to competitors. Understocking causes you to lose revenue, brand reputation and market share.

Scaling your logistics

The challenges of operating a supply chain that processes 100 units/month are very different to the challenges faced by a company selling 10,000 units/month. Ecommerce stores experiencing hyper-growth periods have to deal with transitioning from the former to the latter in a very quick manner.

Scaling your logistics takes effort and attention. A mistake while setting up your supply chain can cause ripple effects that wind up affecting your customer’s experience and diminishing the value of your brand.

Tracking inventory across different platforms

Having a centralized view of your inventory can prevent a number of issues from arising. It is vital for a business to understand how much inventory they have left in real-time, especially for business selling through multiple channels like Amazon, Shopify, Ebay, etc.

Typically this is done through a centralized inventory control software that plugs into your sales channels and tracks inventory turnover across the board. Having visibility of how much inventory you have left and how quickly it is being sold will help with reordering inventory at the right time and in the right quantities.

Lack of data insights

Perhaps the most valuable factor when planning your inventory management practices is understanding not only how your consumers behave but also how your logistics have performed in the past.

Having historical data showing where your logistics have performed well, and where they have been lacking will help you understand what you need to improve about your inventory management practices. This is unfortunately not an option for young companies who have not been in business for long but older businesses derive a lot of their insights from the data tracking of inventory across the entire supply chain.

When should you be thinking about your inventory challenges?

If you’re an eCommerce business that employs a traditional retail model of holding inventory, then inventory management should always be top of mind. It is great to have a product that sells, but not if you run out of stock.

Inventory challenges can be avoided or mitigated by having a backup plan such as temporary dropshipping. This is where a business orders a product directly from a wholesaler or manufacturer to be delivered to their customer without having to pass through your company’s warehouse, bypassing any headaches that may come from not having inventory available. Of course, dropshipping will typically severely delay your shipping times from a regular 3-5 day delivery to something much more delayed such as 14-21 day delivery. Your customers will feel the impact but your brand and your bottom line will thank you for avoiding the stockout.

It is important to have a plan B for when things do go wrong. That’s why you must always be thinking about the challenges that might be lurking around the corner waiting for your record-breaking month.

This is a brief blurb that should summarize what loop does. Maybe it will serve as a brief intro to some of the features?

.png)